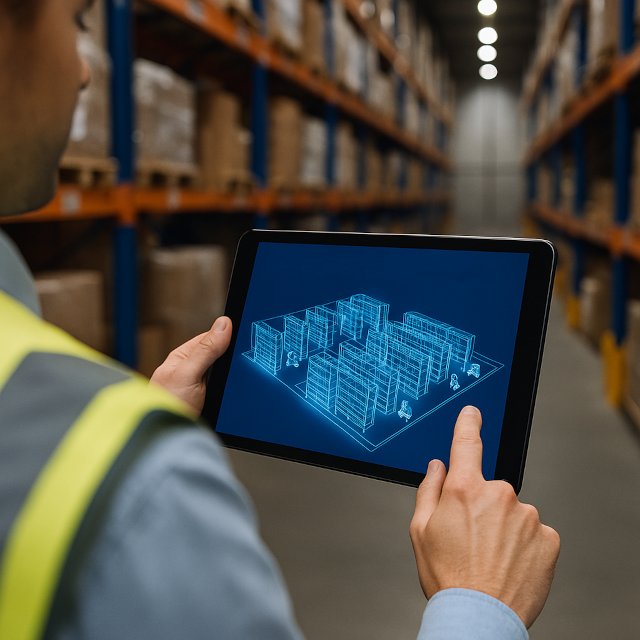

How to Build a Digital Twin for Your Warehouse: Tools, Platforms, and Approaches

From Concept to Reality Digital twin technology is no longer a future-state idea. It’s here—and increasingly accessible to warehouses of all sizes. But once you’ve decided you want one, the next big question is: How do I actually build a digital twin? There’s no one-size-fits-all answer. Some companies adopt twins through their WMS provider. Others […]

How to Build a Digital Twin for Your Warehouse: Tools, Platforms, and Approaches Read More »