Let’s Keep This Simple: What Is a Digital Twin?

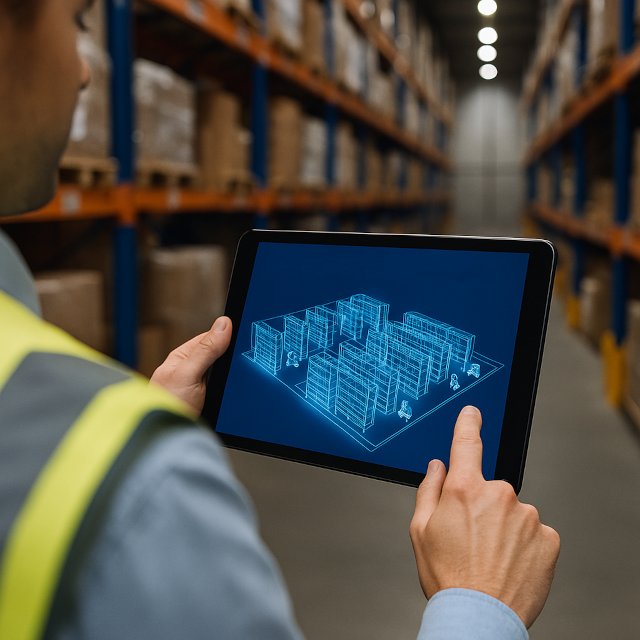

A digital twin is a real-time digital copy of something physical—like a machine, a room, a warehouse, or even a full operation.

It’s not just a drawing or a 3D model.

It’s connected to live data, so when something changes in the real world, it updates in the digital world too.

Imagine you had a “live dashboard” version of your warehouse—showing exactly where everything is, what’s moving, what’s delayed, and what’s about to go wrong. That’s a digital twin.

A Real-World Example

Let’s say you run a distribution center. A digital twin might show:

- Which dock doors are in use

- Where inventory is being stored

- If a forklift is delayed or idle

- Temperature readings in cold storage

- Which staging area is about to overflow

- How the floor layout affects picker travel time

You could then test a “what if” question:

What if I move fast movers closer to dispatch?

What if I reassign pick zones to balance labor?

The digital twin shows you the likely outcome—before you change anything in real life.

So… It’s Like a Simulator?

Yes, but smarter.

A simulator is often static.

A digital twin is live, connected, and learning. It updates automatically using data from:

- Warehouse Management Systems (WMS)

- Sensors (temperature, motion, vibration)

- Scanners and barcodes

- IoT devices

- Real-time tracking systems

It’s not a one-time simulation—it’s a continuous reflection of your real-world operation.

Why Digital Twins Are Taking Off

Digital twins are growing fast in logistics, manufacturing, and facilities management. Why? Because they help you:

- Make better decisions faster

- Reduce downtime

- Catch problems early

- Plan layout changes before disrupting the floor

- Improve safety and compliance (especially in cold chain or pharma)

They turn invisible problems—like bottlenecks or slotting mistakes—into visible, fixable insights.

🔗 Want to see warehouse-specific examples? Read:

Digital Twin Technology for Warehousing: Buzzword or Game Changer?

How Is It Different from a Dashboard or WMS?

Here’s the difference:

| Tool | What It Does |

| WMS | Tells you what’s in stock and where it should be |

| Dashboard | Shows summaries and alerts—often delayed |

| Digital Twin | Shows a live, visual model of your system with context, flow, and prediction |

Think of it this way:

- A dashboard tells you what happened

- A digital twin helps you see what’s happening now—and what could happen next

Is It Only for Big, High-Tech Operations?

Not anymore.

You don’t need full automation or robotics to benefit.

Even small and mid-sized warehouses can use basic digital twin tools:

- 2D floor maps with live updates

- Temperature sensors feeding zone alerts

- Time-motion data to simulate pick paths

- WMS-integrated heatmaps

Many WMS platforms now offer entry-level visualizations that serve as a first step into digital twin territory.

Final Thoughts: Why You Should Care

Digital twins help you:

✅ Visualize problems before they affect operations

✅ Make layout or process changes with confidence

✅ Improve collaboration (everyone sees the same model)

✅ Work proactively instead of reacting too late

It’s not just a fancy tech term—it’s a practical tool for making your operation faster, safer, and more predictable.